Our Solutions

Offshore Wind

We're committed to supporting the decarbonisation of offshore windfarm vessel operations through electrification. Our offshore charging solutions represent a significant step toward reducing greenhouse gas (GHG) emissions in maritime operations.

Stillstrom offers a fully integrated charging solution - from wind farm interface to vessel interface - designed to support wind farm developers in optimising future operations with tailored charging strategies.

Our offshore charging systems enable full-day electric Service Operation Vessel (SOV) operations using a standard up to 8 MW charging solution. The modular design allows integration into new wind farm developments.

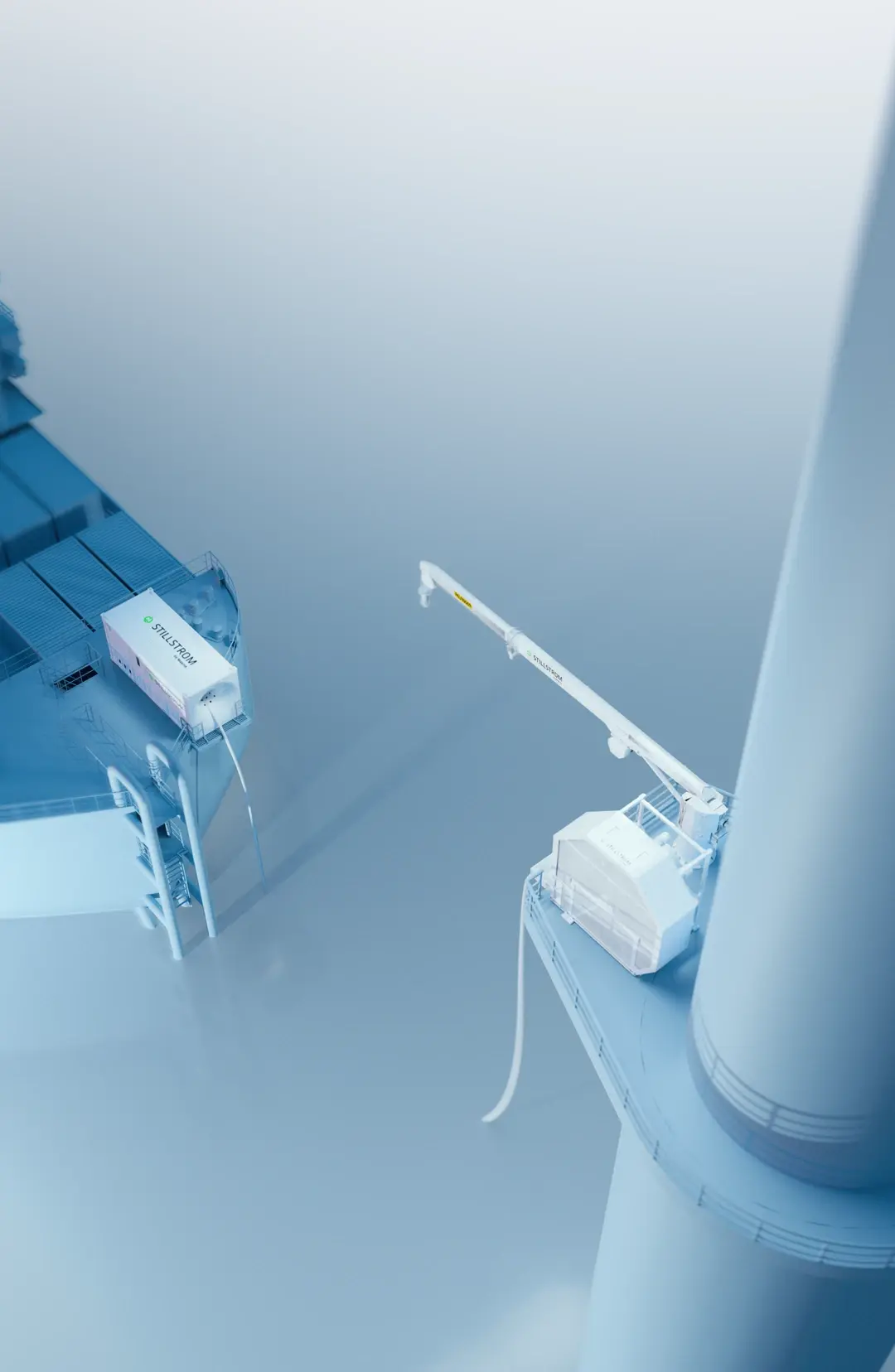

Hang Off System WTG

Service Operation Vessel (SOV) securely connecting to our solution fixed on a wind turbine platform, demonstrating safe and stable power transfer for efficient offshore operations.

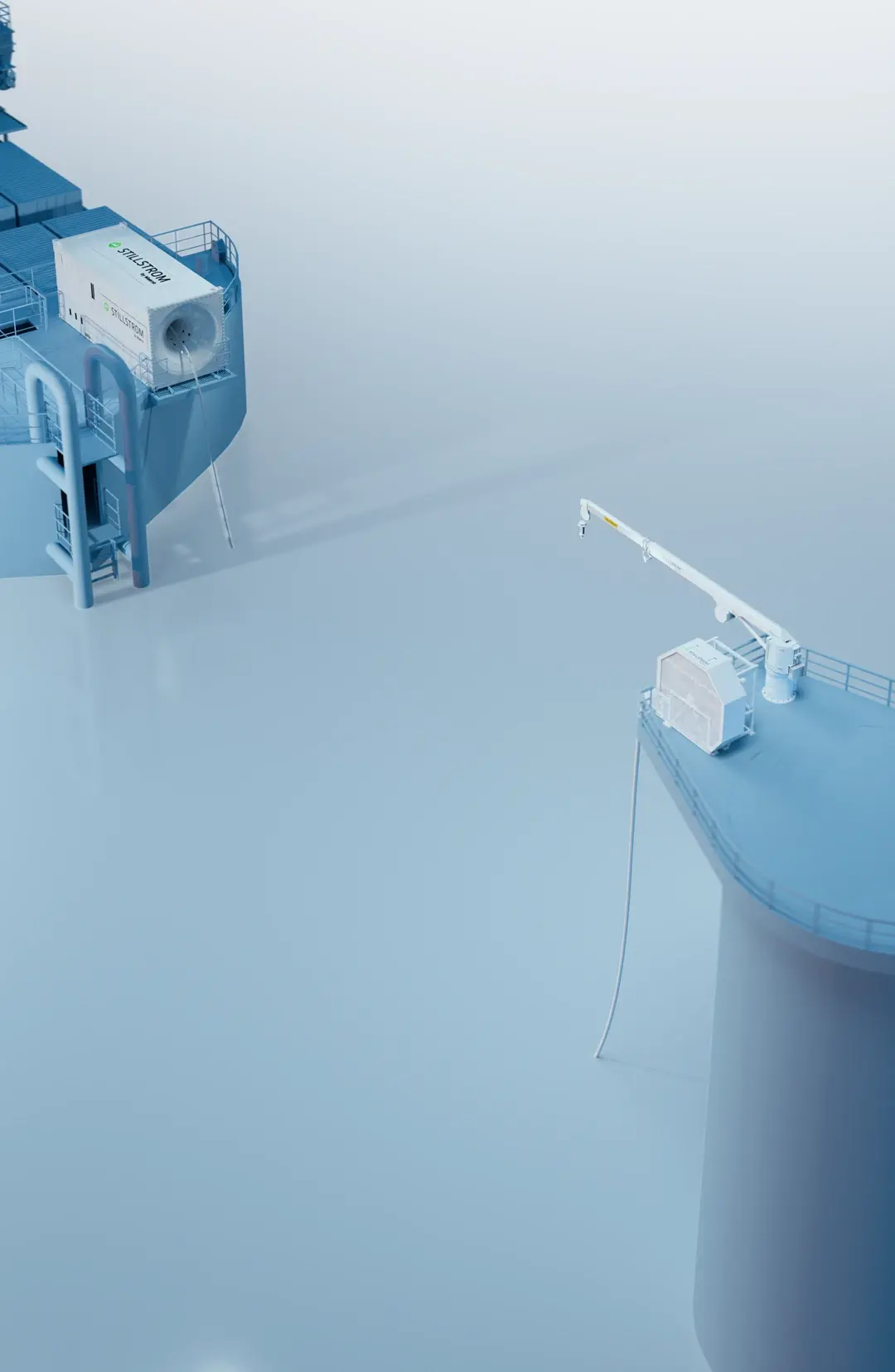

Hang Off System OSS

This video showcases the SOV hooking up and getting power from our solution fixed on an offshore substation, ensuring reliable power supply.

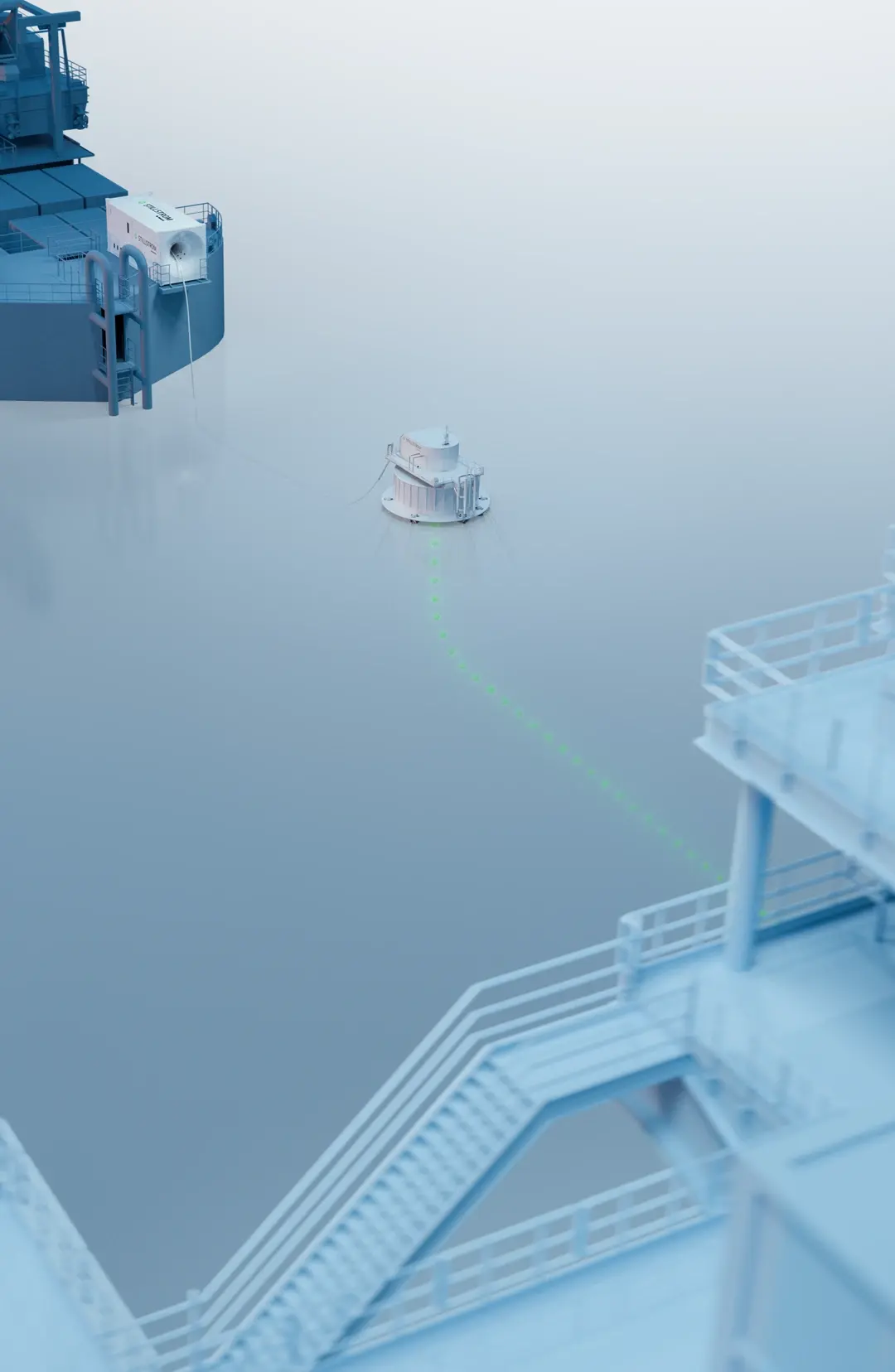

Charging Buoy

See how the SOV connects to a dedicated offshore charging buoy, enabling clean energy transfer for hybrid and electric vessels at sea.

Hang off Solutions

Hang Off System WTG

Hang Off System OSS

Hang Off System Monopile

Buoy Solution

Offshore Charging Buoy

Modularised hang off systems integrated with wind farm structures

Hang Off System WTG

Hang Off System OSS

Hang Off System Monopile

A hang off system is a charging point that hangs off either the OSS, the wind turbine or a monopile, and thereby piggy backs on existing wind farm structure to house the electrical equipment necessary for transformation and conversion of power.

Stillstrom hang off systems are designed for safe and efficient operations. Hook-up, charging operation and disconnect is managed from the vessel and optimised for automated operations. In charging mode the vessel will be positioned in safe distance from critical infrastructure and using limited power on DP.

Benefits

• Offshore charging solutions integrated with existing infrastructure, and with limited changes to existing infrastructure

• Charging operation in safe distance from critical infrastructure

• Solution allows communication through SCADA interface integrated with the main OSP control room

• Designed for safe and reliable operations with operational easy hook up and disconnect

• Option for dual charging facilities on opposite platform directions providing additional redundancy

• Charging system maintenance can be optimised with OSP maintenance and operations team

• Most economical implementation of offshore charging

Offshore Charging Buoy

Offshore Charging Buoy

Stillstrom offshore charging buoy is a floating structure, anchored to the seabed and connected via a dynamic subsea cable to the offshore substation or a wind turbine.

The vessel connects to the buoy with a dynamic power cable. The buoy can house or feed power to the vessel if the equipment is on the substation. It further allows the option to combine offshore charging with secure mooring and weathervaning, thereby reducing energy consumption whilst charging.

The offshore charging buoy allows flexibility in the position of the offshore charging operation in the wind farm. It is designed for a safe and reliable connection and disconnection from the vessel.

Benefits

• The buoy solution allows offshore charging from any location and distance in the wind farm.

• The offshore charging buoy is designed to sustain harsh weather environments, and designed for 100-year storm return conditions.

• The buoy solution provides physical separation from the OSP during charging operations thus removing the risk of contact and interference with any other OSP / vessel operations.

• Options to include mooring and weathervaning, as well as dual vessel charging.

• There are minimal modifications to, or operational impact on the OSP.

Have questions about our solutions for Offshore Wind?

We've compiled answers to the most frequently asked questions to help you understand the benefits and implementation.

Is there redundancy in case the weather limitations are exceeded, power is unavailable?

Yes. All vessels designed to be able to operate fully on battery electric propulsion will still have generators (MGO or green fuels) for redundancy, extreme weather scenarios and emergencies.

Do the solutions enable fully battery electric vessel operations?

The solutions can be designed to enable fully electric operations. The specification of the system is a function of the wind farm size and layout,

metocean conditions, vessel size and type etc. Stillstrom has internal consultancy capabilities to help customers assess technical and operational feasibility for a given wind farm.

Can the solutions be retrofitted to existing wind farms?

Yes, but green field wind farms allow for up front integration, while retrofit may require more tailoring. If you consider introducing battery driven vessels to an existing wind farm, reach out for our support.

What are the benefits of vessel electrification?

The largest benefits are that it enables decarbonised and emissions free vessel operations through eliminating or minimising MGO fuel consumption, with the associated savings that makes for a good business case as well. It is the most energy efficient pathway from electricity to propulsion.

What are the risks of not including electrification on wind farms today?

Wind farms designed today will enter operations towards end of the decade and will be operational beyond 2050. Regulation will change rapidly over the coming years and the risk of having an expensive and outdated service fleet before even commissioning the wind farm is high. Further, public acceptance of burning 1000s of liters of fuel to service each MW of the installed based poses a reputational risk.

What are other value drivers for decarbonisation from the system?

Emission reductions may be eligible for carbon credits, subject to verification and methodology. Stillstrom can advise on this process.

How many systems are required?

Typically 1-2 charging points per offshore wind farm, depending on size, layout, and vessel strategy.

What standard does the charger use?

There is no standard yet, but Stillstrom follows the shore power standards and all relevant standards for offshore electrical systems.